Features

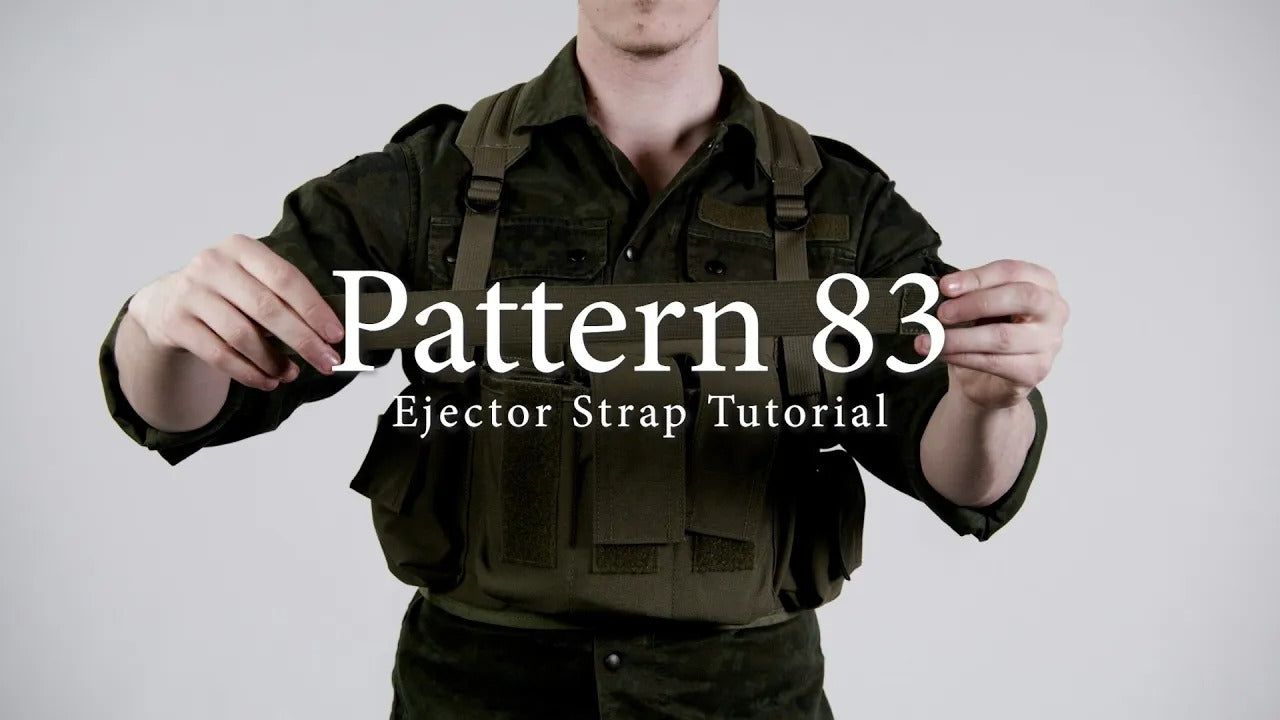

Ejector Straps

• Ejector straps are designed to offer backwards compatibility with FN FAL (R1) magazines and improve the performance of Galil (R4) magazines. In our testing they work well with many magazines which are shorter than the standard 35 round Galil mag, including 30 round STANAG magazines popular on the Armalite Rifle 15 and its derivatives.

• After rigorous internal testing and overwhelming customer feedback we decided to make our ejector straps removeable. This is a small departure from original early-pattern chest rigs however the added utility of removable straps cannot be ignored. So we've switched out permanent stitching in favor of sturdy velcro.

Pouches

• The central magazine pouches hold up to 6 magazines in 3 rows of 2. The cells are made for Galil magazines, but are compatible or partially compatible with STANAG, FAL, G3, AK 47, AK 74, and AK 5.56 magazines.

• The large right pocket is designed to fit a smoke or frag grenade. In practice this pouch works great for small water bottles, miscellaneous loose tools, and extra medical supplies. What you put here really depends on if you are wearing a belt or a fanny pack in addition to the chest rig.

• The two smaller pockets on the left are designed to fit a single fragmentation grenade and a compass respectively. We’ve found they work well for storing weapon lube, cleaning supplies, other smaller items.

• On the inside of the rig, a large admin pouch comfortably accommodates and protects maps, notebooks, and writing utensils.

• A small pen flare pocket is attached to the left side of the central magazine pouches. It’s a great spot for a grease or paint pen.

Specs

- 1000D PU Coated Cordura fabric

- Milspec ITW Fastex & Slider hardware

- Milspec hook and loop fasteners

- Milspec webbing and binding tape

- High quality bonded nylon thread

- All materials are Berry compliant

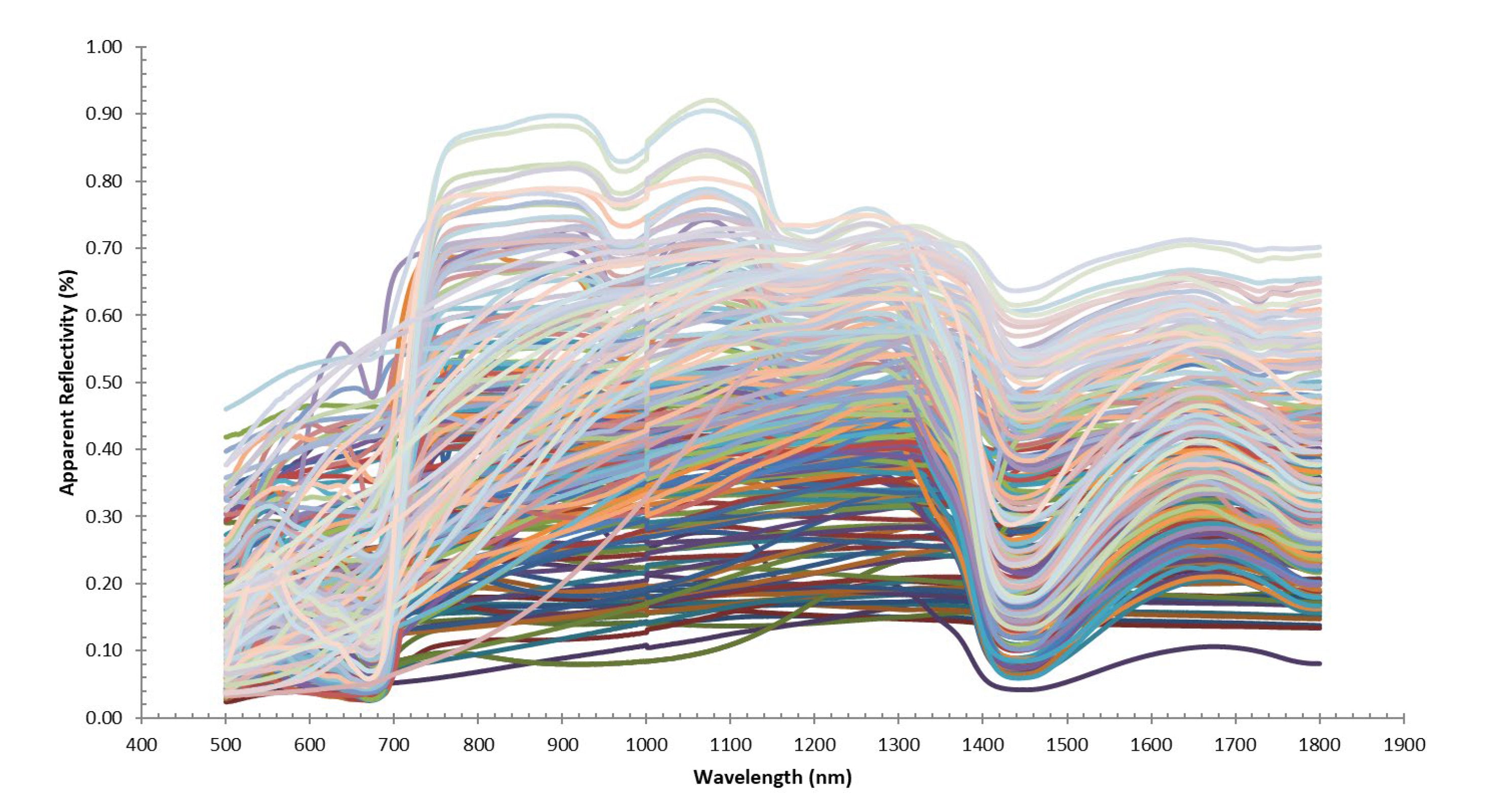

- All materials are NIR compliant